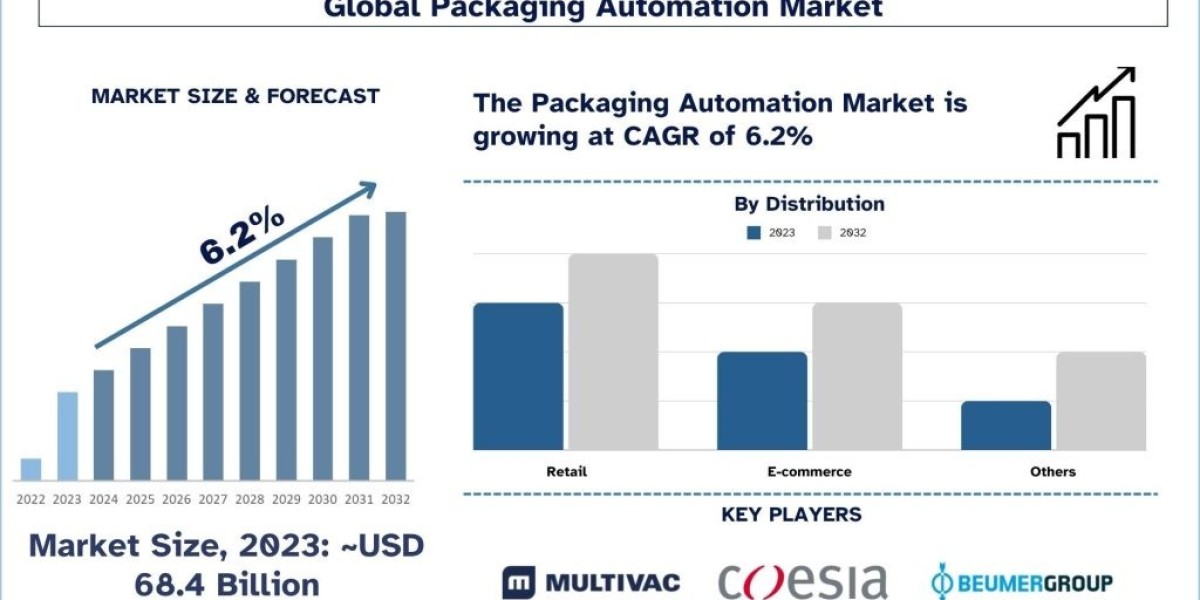

According to the UnivDatos Market Insights analysis, the booming e-commerce sector demands fast and efficient packaging solutions, driving the adoption of automation. Furthermore, the global shortage of skilled labor is pushing industries to adopt automated packaging solutions to maintain productivity. The Automated Packaging Market was valued at USD 68.4 billion in 2023, growing at a CAGR of 6.2% during the forecast period from 2024 - 2032 to reach USD billion by 2032. The global packaging automation market is still growing at a very fast rate due to the increased adoption of new technology by firms in the packaging sector. In the light of increasing customer requirements for better, cheaper, and more environmentally friendly packaging solutions, automation plays a crucial role for companies that want to remain successful on the market.

Access sample report (including graphs, charts, and figures): https://univdatos.com/get-a-free-sample-form-php/?product_id=65815

Sustainability in Packaging Automation

Another key trend observed in the packaging automation market is the increasing concentration on environmentally friendly solutions. This change is prompted by pressure from the consumers, the regulators, and other stakeholders who are concerned with the environment and the effects of carbon footprint and waste.

Sustainable Packaging Materials: Some of the contemporary packaging systems have been developed to incorporate the use of environmentally friendly materials such as biodegradable plastics, and recycled paper among others. This is due to the increasing global concern about the packaging that meets the environmental standards which include the European Union circular economy action plan.

Energy-Efficient Machinery: Packaging automation manufacturers are also working towards developing machines that consume less energy while packaging. The use of energy-efficient equipment assists firms in reducing their operational costs while at the same achieving their sustainable development objectives. Considering carbon emission standards, energy-efficient packaging solutions are gaining more importance.

The use of Artificial Intelligence and Robotics

AI and robotics have brought a paradigm shift in the field of packaging automation with the ability to offer high efficiency, accuracy, and flexibility.

AI-Driven Systems: With the use of AI in packaging automation systems, it is possible to capture and analyse data and make decisions instantly. The use of AI algorithms makes it possible to analyze the data coming from the packaging lines to ensure efficient operation, determine when certain parts may require servicing, and even control the flow of work. For instance, AI can diagnose faults in the packaging or control the speeds of the machines according to the production needs thus reducing time losses and minimizing waste.

E-Commerce Boom Driving Automation

Today’s fast-growing e-commerce industry has raised the bar for packaging requirements. Given the trend of the growth of the global e-commerce market, packaging automation is becoming a necessity for companies that must adapt to the increasing number of online orders.

Customization and Flexibility: The first major problem of e-commerce packaging is the diverse nature of products that are shipped to clients. In the current world, packaging systems are being automated to be able to work on different sizes, shapes, and weights of products to package. Others include print-on-demand labels as well as variable box sizes that have been enhanced by technology to help companies meet the needs of consumers while still in the production process.

Smart Packaging and Internet of Things.

The rise of IoT has introduced smart packaging which is changing the way that companies implement packaging automation. IoT technologies enable packaging systems to interconnect with other systems and databases to acquire real-time information on the packaging process.

Smart Sensors: It entails the use of packaging that has sensors to check for factors such as temperature and humidity among others. These sensors are particularly helpful in sectors such as the pharmaceutical or food industries as the packing environment can impact the quality of the final product. Using IoT sensors, the products are well packaged and stored in the right conditions thereby minimizing cases of spoilage or contamination.

The Emergence of Self-Guided Packaging Technologies

Automated packaging systems are becoming popular in the market since there is less involvement of humans when packaging the products. These systems are autonomous and employ AI, robotics, and IoT to function from the loading of the product to packing of the same without human intervention.

Self-Optimizing Machines: The use of self-governing packaging machines is that they can alter their functioning depending on the information received. For instance, these systems can detect constraints in packaging and the systems can adjust themselves in a way that enhances the flow rate. This level of automation decreases the level of monitoring, allowing the operators to address more intricate tasks.

Cost-Effective Solutions for SMEs

Although packaging automation has been mainly linked to big corporations, SMEs are now searching for affordable automation options to meet market challenges.

Modular Automation Systems: The following is one of the ways through which automation has been made accessible to SMEs; the development of modular automation systems. These systems are scalable; this means that companies can invest in automation depending on the amount of money they are willing to spend. Modular systems allow companies to integrate automation modules when they need it, thus reducing the investments needed at the beginning, but still getting the benefits of automation.

Click here to view the Report Description & TOC https://univdatos.com/report/packaging-automation-market/

Conclusion

The global packaging automation market will keep on developing as firms across sectors continue to understand the advantages of increased efficiency, decreased expenses, and better packaging standards. The advancement in technology especially in the field of artificial intelligence, robotics, and smart packaging is also contributing to this growth, and automation is being seen as a major innovation driver in the packaging industry. However, there are still some issues with packaging automation, however, the potential for increasing overall efficiency, reducing costs, and expanding the scale of production makes automation one of the most important investments for companies that are aimed at becoming leaders in the market.

Related Report

Cyber Insurance Market: Current Analysis and Forecast (2024-2032)

Digital Human Avatar Market: Current Analysis and Forecast (2024-2032)

Virtual Influencers Market: Current Analysis and Forecast (2024-2032)

Diversity and Inclusion (D&I) Market: Current Analysis and Forecast (2024-2032)

Container Orchestration Market: Current Analysis and Forecast (2024-2032)

Contact Us:

UnivDatos Market Insights

Email - contact@univdatos.com

Contact Number - +1 9782263411

Website - https://univdatos.com/