Reinforcing bar, commonly known as rebar, is a crucial material used in construction to enhance the tensile strength of concrete structures. As a vital component in infrastructure projects, understanding the price trend of rebar is essential for construction firms, contractors, and investors. This article will explore the factors influencing rebar prices, recent trends, and future forecasts.

1. Understanding Rebar

Rebar is typically made from steel and comes in various grades and sizes. It is used to reinforce concrete in a wide range of applications, including buildings, bridges, highways, and more. The quality and specifications of rebar can significantly impact its performance and cost.

2. Factors Influencing Rebar Prices

Several key factors affect the pricing of rebar:

a. Raw Material Costs

The primary ingredient in rebar production is steel, which is derived from iron ore. Fluctuations in the prices of raw materials like iron ore, scrap metal, and coal directly impact rebar costs.

- Market Volatility: Global demand for steel, driven by industrial activity and construction projects, can lead to significant price variations.

Request For Free Sample: https://www.procurementresource.com/resource-center/rebar-price-trends/pricerequest

b. Production Costs

The manufacturing process for rebar includes several stages: melting, casting, and rolling. Each step requires energy, labor, and technology, all of which contribute to overall production costs.

- Energy Prices: The cost of electricity and natural gas can influence production expenses, especially in energy-intensive processes.

c. Supply and Demand Dynamics

The balance between supply and demand is a crucial determinant of rebar prices. When demand outpaces supply, prices tend to rise.

- Construction Activity: Increased construction activity, especially in emerging markets, can drive demand for rebar, impacting prices.

d. Economic Indicators

Macroeconomic factors such as GDP growth, inflation rates, and construction spending play a significant role in shaping demand for rebar.

- Economic Growth: A robust economy typically leads to higher construction spending, subsequently increasing demand for rebar.

e. Trade Policies and Tariffs

Government regulations and tariffs can influence the cost of importing raw materials and finished products.

- Import Tariffs: Changes in trade policies can affect the availability and cost of imported steel, which in turn impacts domestic rebar prices.

3. Recent Price Trends

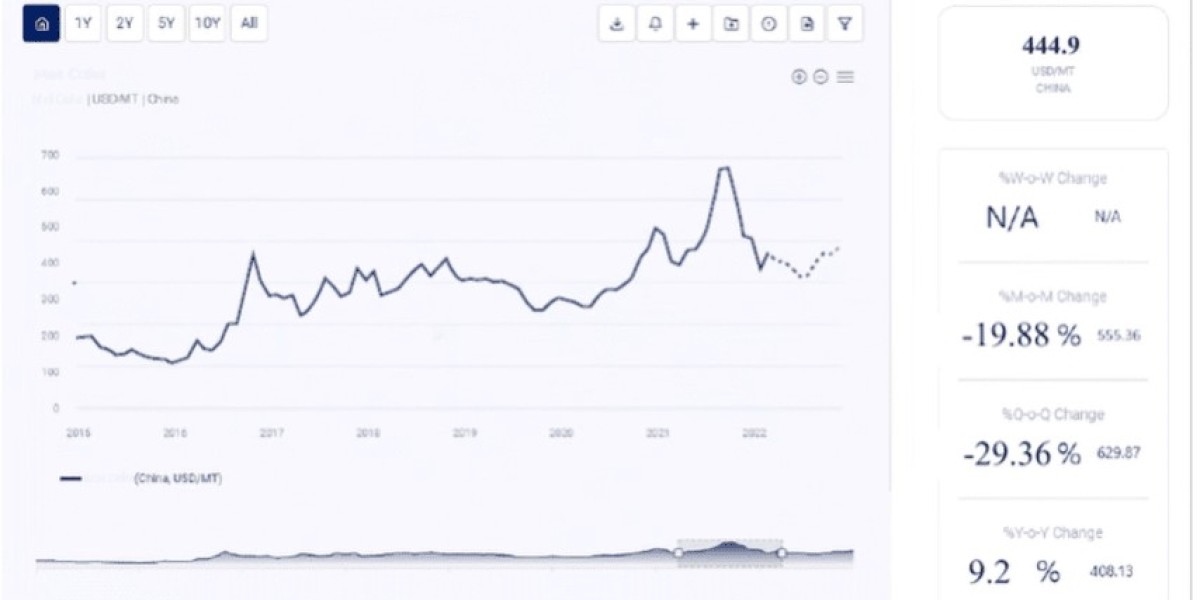

In recent years, rebar prices have experienced considerable fluctuations. Key trends include:

a. Price Increases

- 2020-2021 Surge: Following the COVID-19 pandemic, rebar prices saw a sharp increase due to supply chain disruptions, higher raw material costs, and a resurgence in construction activities.

b. Volatility in 2022-2023

- Global Market Uncertainty: Geopolitical tensions, such as conflicts affecting major steel-producing regions, have introduced volatility in the rebar market.

c. Current Trends

- Stabilization: As of 2024, rebar prices have shown signs of stabilization, with market participants cautiously optimistic about steady demand in construction projects.

4. Future Forecasts

Looking ahead, several factors will shape the future of rebar prices:

a. Continued Demand

With infrastructure development gaining momentum in various countries, especially in Asia and Africa, demand for rebar is expected to remain strong.

b. Sustainable Practices

The construction industry's shift toward sustainability may impact rebar production methods, potentially affecting costs.

c. Technological Advancements

Improvements in manufacturing efficiency and recycling practices could help mitigate some production costs, influencing overall pricing.

Contact Us:

Company Name: Procurement Resource

Contact Person: Leo Frank

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada — Phone no: +1 307 363 1045 | UK — Phone no: +44 7537 132103 | Asia-Pacific (APAC) — Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA