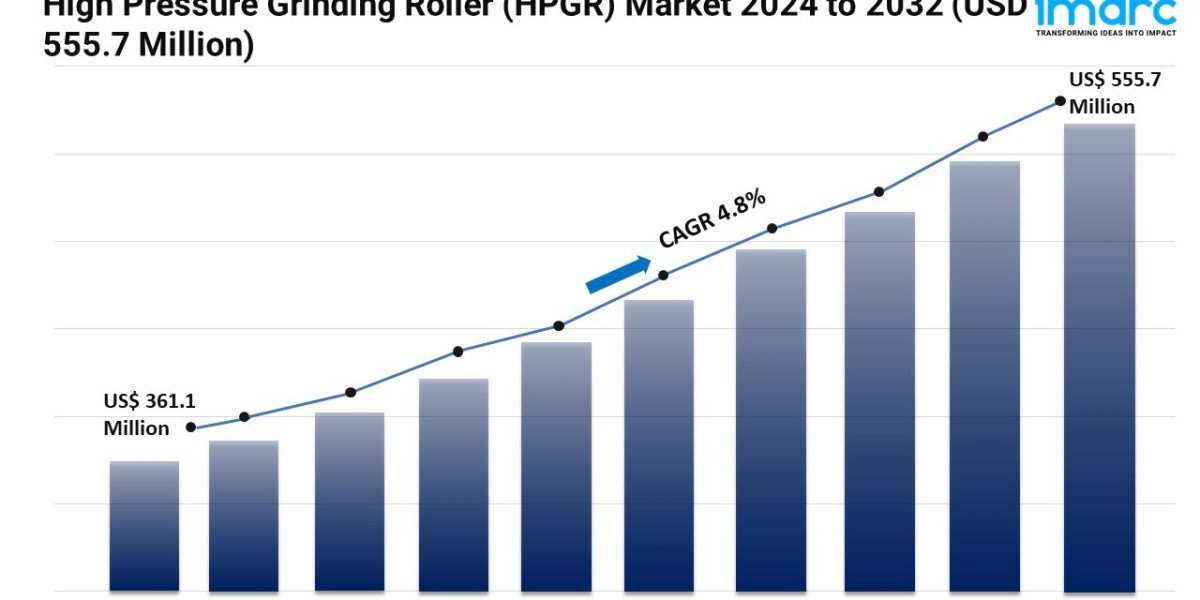

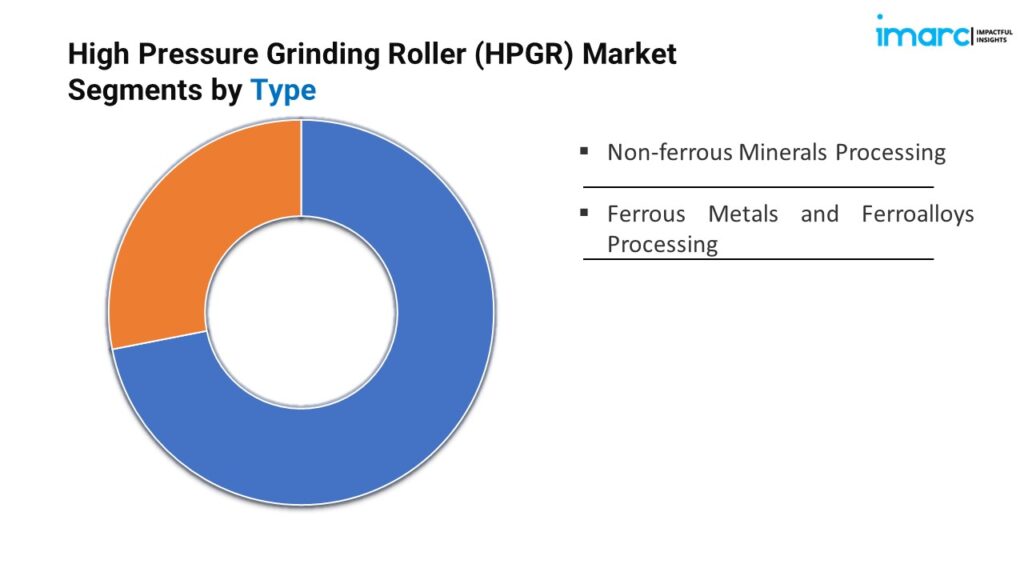

IMARC Group's report titled "High Pressure Grinding Roller (HPGR) Market Report by Type (Non-ferrous Minerals Processing, Ferrous Metals and Ferroalloys Processing), Power Rating (2 x 100 kW - 2 x 650 kW, 2 x 650 kW - 2 x 1,900 kW, 2 x 1,900 kW - 2 x 3,700 kW, 2 x 3,700 kW and Above), Application (Precious Metal Beneficiation, Diamond Liberation, Base Metal Liberation, Pellet Feed Preparation), End Use Industry (Cement, Ore and Mineral Processing, and Others), and Region 2024-2032". The global high pressure grinding roller hpgr market size reached US$ 361.1 Million in 2023. Looking forward, IMARC Group expects the market to reach US$ 555.7 Million by 2032, exhibiting a growth rate (CAGR) of 4.8% during 2024-2032.

Grab a sample PDF of this report: https://www.imarcgroup.com/high-pressure-grinding-roller-market/requestsample

Factors Affecting the Growth of the High Pressure Grinding Roller (HPGR) Industry:

- Energy Efficiency and Sustainability:

The increasing emphasis on energy efficiency and sustainability in the mining and minerals industry is impelling the growth of the market. High pressure grinding roller (HPGR) technology is recognized for its ability to reduce energy consumption compared to traditional milling processes. This substantial reduction in energy usage translates into lower operational costs and a smaller carbon footprint, aligning with global efforts to mitigate environmental impacts. The mining sector, being energy-intensive, faces the growing regulatory pressures to adopt greener technologies, and the ability of high pressure grinding roller HPGR to enhance the efficiency of mineral processing while conserving energy makes it an attractive choice.

- Increasing Demand for Precious Metals and Minerals:

The global rise in demand for precious metals and minerals is a pivotal factor propelling the market. Rapid industrialization and urbanization are leading to an increase in the consumption of base and precious metals. HPGR technology is particularly advantageous in processing hard and abrasive ores, which are increasingly being mined to meet this demand. The ability of HPGR to enhance the liberation of valuable minerals and improve recovery rates is crucial in the context of declining ore grades worldwide. As ore bodies become more complex and harder to process, mining companies are increasingly adopting HPGR technology to maximize yield and ensure the economic viability of mining projects.

- Technological Advancements and Innovations:

Ongoing advancements and continuous innovations in HPGR technology are supporting the market growth. Moreover, significant improvements have been made in the design and performance of HPGRs, including the development of wear-resistant materials, enhanced control systems, and improved roller designs. These innovations are increasing the reliability and longevity of HPGR equipment, reducing downtime and maintenance costs. Additionally, advancements in automation and process control technologies are enabling better optimization of the grinding process, resulting in higher throughput and efficiency. The integration of advanced sensors and real-time monitoring systems allows for precise control over operational parameters, enhancing the overall performance and productivity of HPGR installations.

Explore full report with table of contents: https://www.imarcgroup.com/high-pressure-grinding-roller-market

Leading Companies Operating in the Global High Pressure Grinding Roller HPGR Industry:

- ABB Ltd.

- AGICO Cement Plant

- CITIC Heavy Industries Co. Ltd.

- FLSmidth & Co. A/S

- KHD Humboldt Wedag International AG

- Maschinenfabrik Köppern GmbH & Co. KG

- Metso Outotec Oyj, SGS S.A.

- Sunkaier

- TAKRAF GmbH

- The Weir Group PLC and thyssenkrupp Industrial Solutions AG (thyssenkrupp AG)

High Pressure Grinding Roller (HPGR) Market Report Segmentation:

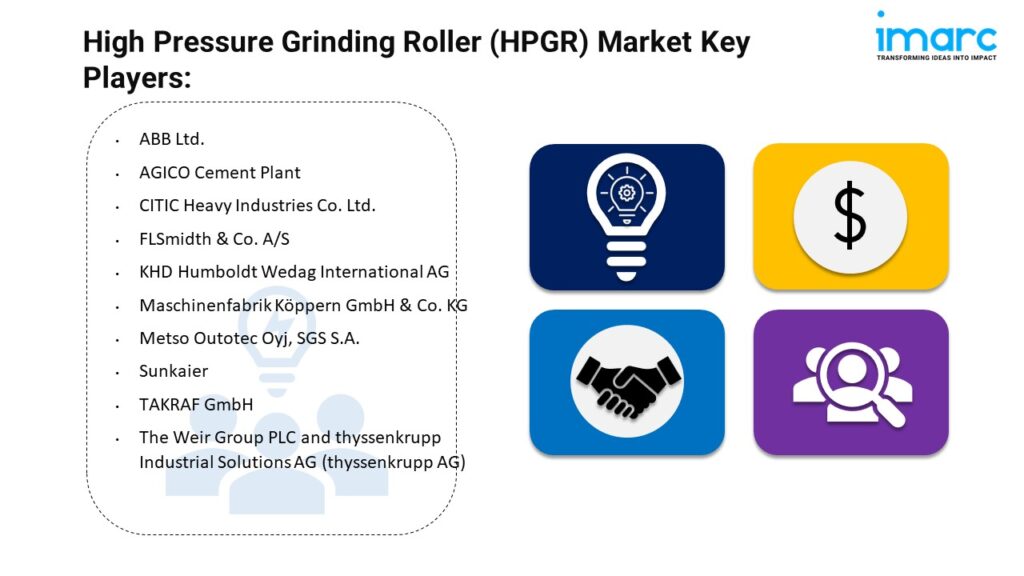

By Type:

- Non-ferrous Minerals Processing

- Ferrous Metals and Ferroalloys Processing

Non-ferrous minerals processing holds the biggest market share due to the extensive use of these minerals in industrial applications, such as aluminum, copper, and zinc production, which are essential for various manufacturing and construction industries.

By Power Rating:

- 2 x 100 kW - 2 x 650 kW

- 2 x 650 kW - 2 x 1,900 kW

- 2 x 1,900 kW - 2 x 3,700 kW

- 2 x 3,700 kW and Above

Based on the power rating, the market has been divided into 2 x 100 kW - 2 x 650 kW, 2 x 650 kW - 2 x 1,900 kW, 2 x 1,900 kW - 2 x 3,700 kW, 2 x 3,700 kW and above.

By Application:

- Precious Metal Beneficiation

- Diamond Liberation

- Base Metal Liberation

- Pellet Feed Preparation

Precious metal beneficiation represents the leading segment driven by the high demand and value of precious metals like gold, silver, and platinum, which are critical for investment, jewelry, and industrial applications.

By End Use Industry:

- Cement

- Ore and Mineral Processing

- Others

On the basis of the end use industry, the market has been classified into cement, ore and mineral processing, and others.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific's dominance in the high pressure grinding roller (HPGR) market is attributed to its large-scale mining activities, rapid industrialization, and the presence of significant mineral reserves.

Global High Pressure Grinding Roller (HPGR) Market Trends:

The increasing cost reduction and operational efficiency it offers to mining operations. HPGR technology reduces the need for secondary crushing and grinding, which directly lowers the overall energy consumption and operating costs. The high-pressure environment created by HPGR results in micro-cracking within the ore, enhancing the downstream leaching or flotation processes, which leads to higher recovery rates and lower processing costs. Additionally, HPGR systems require less maintenance compared to traditional milling equipment due to their robust design and advanced wear-resistant materials. This reduced maintenance translates into higher uptime and productivity. As mining companies continuously seek ways to optimize their operations and reduce costs, the economic advantages offered by HPGR technology become increasingly attractive.

Note: If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARCs information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145