The stainless steel market plays a vital role in various industries, from construction and automotive to consumer goods and medical devices. As global demand for durable, corrosion-resistant materials grows, stainless steel continues to evolve. In the coming years, the market will be shaped by technological advancements, sustainability initiatives, and emerging opportunities. Here’s a look at the key innovations and opportunities that will define the future of the stainless steel market.

1. Sustainable Production and Circular Economy Initiatives

One of the most significant trends in the stainless steel market is the growing focus on sustainability and the transition to a circular economy. Stainless steel is already one of the most recycled materials, with up to 90% of stainless steel being made from recycled scrap. However, manufacturers are now aiming to reduce their carbon footprints even further through innovations in production processes and recycling technologies.

- Low-carbon stainless steel production is becoming a priority, with companies investing in green technologies such as electric arc furnaces powered by renewable energy. This shift is helping reduce the carbon emissions associated with stainless steel production.

- The development of new, eco-friendly alloys with reduced nickel and chromium content is another area of innovation, aimed at lowering the environmental impact of stainless steel manufacturing while maintaining its strength and corrosion resistance.

- Recycling advancements are making it easier to recover high-quality stainless steel from scrap, reducing the need for virgin raw materials and aligning with global efforts to adopt more sustainable practices in manufacturing.

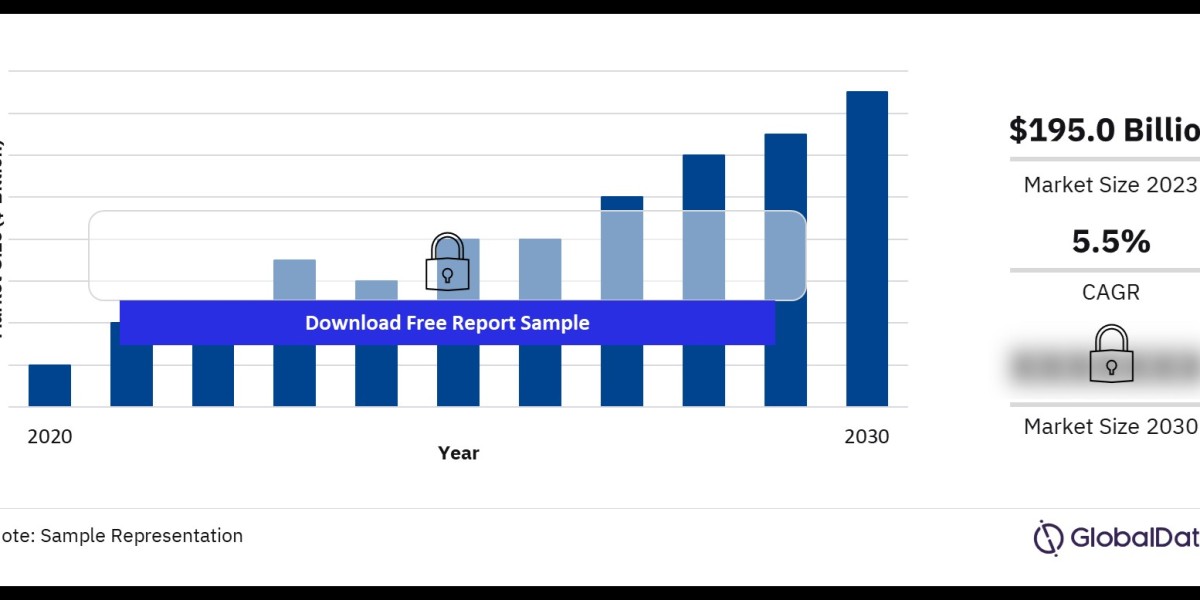

Buy the Full Report for Additional Insights on the Stainless Steel Market Forecast

2. 3D Printing and Additive Manufacturing

The adoption of 3D printing and additive manufacturing in the stainless steel industry is revolutionizing the way products are designed and manufactured. This technology allows for the creation of complex geometries and customized parts that would be difficult or impossible to produce using traditional methods.

- Stainless steel 3D printing is being used in industries such as aerospace, medical devices, and automotive, where precision and material strength are critical. By using stainless steel powders in additive manufacturing, companies can produce lighter, stronger components with minimal material waste.

- The ability to customize products on demand through 3D printing offers significant opportunities for manufacturers to respond quickly to changing customer needs and market demands. It also reduces lead times and production costs, making stainless steel products more accessible for various applications.

3. Advanced Coatings and Surface Treatments

Innovations in coating technologies and surface treatments are expanding the range of applications for stainless steel, particularly in harsh environments where corrosion resistance and durability are critical.

- Nano-coatings and ceramic-based coatings are being developed to enhance the corrosion resistance of stainless steel, even in extreme conditions such as marine environments, chemical processing plants, and offshore oil platforms.

- Self-healing coatings represent another promising innovation, providing stainless steel with the ability to repair minor surface damage automatically. These coatings help extend the lifespan of stainless steel products and reduce maintenance costs.

- Anti-microbial coatings are gaining traction in the medical and food processing industries, where hygiene is a top priority. These coatings can prevent bacterial growth on stainless steel surfaces, making them ideal for use in hospitals, kitchens, and cleanroom environments.

4. Emerging Markets and Infrastructure Development

As developing regions, particularly in Asia, Africa, and Latin America, continue to industrialize and urbanize, the demand for stainless steel is expected to surge. Infrastructure projects in these regions are driving significant growth in the stainless steel market, particularly in sectors such as construction, transportation, and energy.

- Urbanization and population growth in emerging markets are creating a demand for stainless steel in the construction of buildings, bridges, and transportation systems. Stainless steel’s strength, durability, and resistance to corrosion make it ideal for infrastructure that needs to withstand harsh environmental conditions.

- The expansion of renewable energy projects, such as solar, wind, and hydropower installations, also presents opportunities for the stainless steel market. Stainless steel is commonly used in these industries for structural components, turbines, and pipelines due to its high strength and ability to withstand extreme weather conditions.

5. Automotive Industry Transformation

The automotive industry is undergoing a significant transformation, driven by the shift toward electric vehicles (EVs) and the development of lightweight, energy-efficient materials. Stainless steel is poised to play a crucial role in this transition, as automakers look for materials that offer both strength and weight reduction.

- Stainless steel alloys are being developed to meet the needs of the EV market, offering enhanced strength and corrosion resistance while being lighter than traditional materials. This helps improve vehicle efficiency by reducing overall weight, which is particularly important for electric vehicles that rely on battery power.

- Stainless steel is also being used in the production of hydrogen fuel cells, which are seen as a promising alternative to battery-powered EVs. The material’s ability to withstand high temperatures and corrosive environments makes it an ideal choice for fuel cell components.

6. Growth of Stainless Steel in Healthcare and Medical Devices

The healthcare and medical device industries are significant consumers of stainless steel due to its biocompatibility, sterility, and resistance to corrosion. As these sectors continue to grow, particularly with an aging global population and advancements in medical technology, demand for stainless steel is expected to rise.

- Surgical instruments, implants, and medical equipment made from stainless steel are critical in ensuring patient safety and reducing the risk of infections. The material’s strength and durability make it a preferred choice for medical devices that need to withstand repeated sterilization and usage.

- Innovations in stainless steel alloys are improving the performance of medical implants, such as orthopedic and dental devices, by enhancing their compatibility with the human body and reducing the risk of rejection or corrosion.

7. Digitalization and Smart Manufacturing

The rise of Industry 4.0 is transforming stainless steel production through the integration of digital technologies such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT). These technologies are helping manufacturers optimize their production processes, reduce waste, and improve product quality.

- AI-powered analytics are being used to monitor equipment performance and predict maintenance needs, reducing downtime and improving operational efficiency. By analyzing data from production lines, manufacturers can identify inefficiencies and optimize workflows in real-time.

- IoT-enabled sensors are being implemented in stainless steel manufacturing plants to monitor key parameters such as temperature, pressure, and energy consumption. This helps manufacturers reduce energy use and minimize waste, aligning with sustainability goals.

8. New Applications in Renewable Energy

As the world shifts toward renewable energy sources, stainless steel is finding new applications in emerging technologies such as wind turbines, solar panels, and geothermal energy systems.

- Wind turbines rely on stainless steel for critical components such as shafts, bearings, and fasteners, which need to withstand extreme environmental conditions and corrosion. As offshore wind farms expand, demand for stainless steel in the renewable energy sector is expected to grow.

- In solar energy, stainless steel is used in the mounting systems for solar panels, ensuring that they can endure outdoor environments for decades without degrading. The durability and low maintenance requirements of stainless steel make it an ideal material for long-term renewable energy infrastructure.

- Geothermal energy systems also use stainless steel for pipelines, heat exchangers, and drilling equipment, as the material is able to withstand the high temperatures and corrosive fluids involved in geothermal power generation.

Conclusion

The future of the stainless steel market is marked by innovation and opportunity across a wide range of industries. With a focus on sustainability, advanced manufacturing techniques, and expanding applications in emerging markets and renewable energy, stainless steel is well-positioned to remain a critical material in the global economy. As industries continue to demand stronger, lighter, and more eco-friendly materials, stainless steel will play a central role in meeting these needs, ensuring its continued growth and relevance in the years to come.

Search

Popular Posts

-

জিতাএস বাংলাদেশ ক্যাসিনো: অনলাইন ক্যাসিনো গেমিংয়ের সেরা ঠিকানা

জিতাএস বাংলাদেশ ক্যাসিনো: অনলাইন ক্যাসিনো গেমিংয়ের সেরা ঠিকানা

-

Топ 10 Преимуществ казино Драгон Мани

By topcasino777

Топ 10 Преимуществ казино Драгон Мани

By topcasino777 -

Car GPS Tracking Device: What Makes Fleettrack the Best Choice for Real-Time Tracking?

By fleettrackin

Car GPS Tracking Device: What Makes Fleettrack the Best Choice for Real-Time Tracking?

By fleettrackin -

GPS Tracker Car Fleettrack: Secure & Reliable Tracking Deals

By fleettrackin

GPS Tracker Car Fleettrack: Secure & Reliable Tracking Deals

By fleettrackin -

Почему Драгон Мани такое популярное онлайн-казино?

By topcasino777

Почему Драгон Мани такое популярное онлайн-казино?

By topcasino777