When it comes to roofing systems, the underlayment plays a critical role in ensuring long-term durability, protection, and overall performance. In regions where heavy rain and snow are common, choosing the right roofing underlayment is crucial to maintaining the integrity of the roof and preventing water damage. High-performance roofing underlayment is specifically designed to withstand extreme weather conditions such as heavy rainfall and snow loads, offering superior protection to both the roof structure and the building beneath. In this article, we will explore the features and benefits of high-performance roofing underlayment and its importance in heavy rain and snow load scenarios. Additionally, we will delve into the role of Roofing underlayment supplier, with a focus on the growing demand for roof underlayment in India.

The Importance of Roofing Underlayment in Protecting the Roof

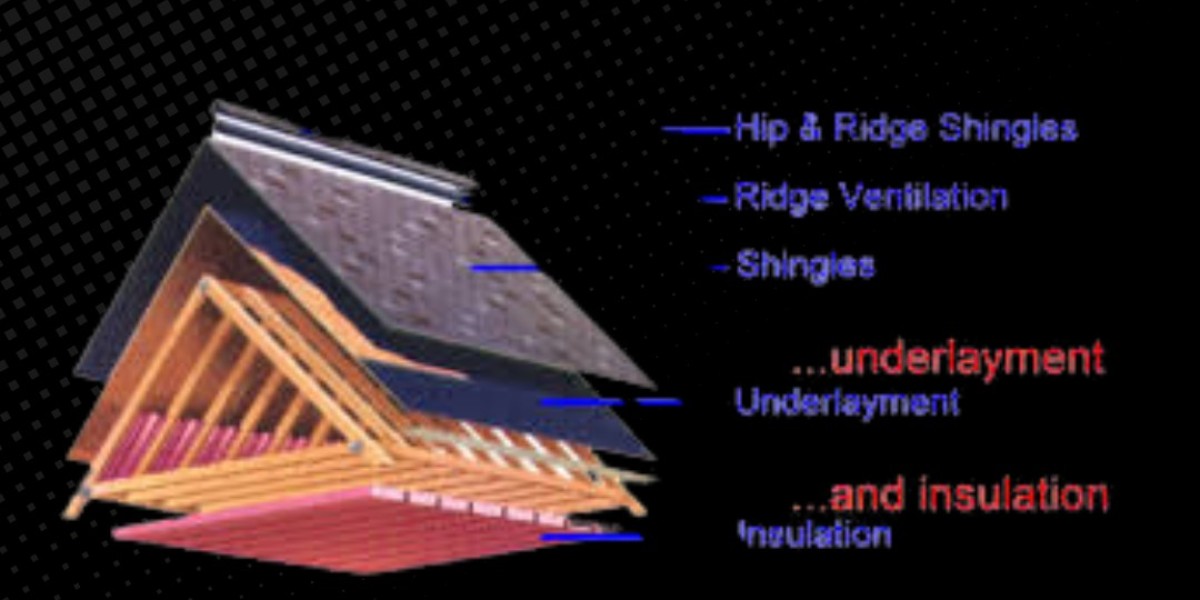

Roofing underlayment serves as an essential protective layer beneath the primary roofing material, typically shingles or tiles. Its primary function is to provide an additional barrier against moisture infiltration. During heavy rainfall or snow accumulation, roofs are vulnerable to water seepage, which can lead to mold, wood rot, and structural damage. The underlayment acts as a shield, preventing water from reaching the underlying roof deck and ensuring that the home remains dry and secure. For regions prone to heavy rain and snow, it becomes even more critical to choose a high-performance roofing underlayment capable of handling these extreme conditions.

A high-quality roofing underlayment helps distribute the weight of snow and rain, thereby reducing the risk of leaks and ensuring that the roof remains stable under stress. It also provides an added layer of insulation, keeping the home more energy-efficient during winter months when snow accumulation is significant. As a result, homeowners should look for roofing underlayment that offers both superior water resistance and the ability to endure harsh weather patterns.

Benefits of High-Performance Roofing Underlayment

High-performance roofing underlayment is designed to offer enhanced durability and superior protection. Unlike traditional felt underlayments, which may degrade over time, high-performance underlayment materials are engineered to withstand the harshest conditions, including heavy rainfall, snow loads, and extreme temperature fluctuations. Some of the key benefits of high-performance roofing underlayment include:

Waterproofing and Moisture Resistance: The primary benefit of high-performance roofing underlayment is its ability to provide a waterproof barrier. Whether it's heavy rain or melting snow, these underlayments ensure that moisture does not penetrate the roof structure.

Enhanced Durability: Roofing underlayment made from synthetic materials, such as polypropylene or polyester, is far more durable than traditional felt. These materials are resistant to tears, punctures, and degradation, which makes them ideal for areas with heavy snow and rain.

Protection Against Ice Dams: In areas where snow is common, ice dams can form on the roof, preventing melting snow from draining off properly. High-performance underlayment helps mitigate this risk by providing a solid moisture barrier that resists ice penetration.

Better Weather Resistance: Extreme weather conditions, such as high winds, heavy rain, and snow, can wreak havoc on a roof. High-performance underlayment provides extra protection against these elements, helping to keep the home safe and dry.

Improved Energy Efficiency: A high-performance roofing underlayment can also help with temperature regulation inside the home by adding an extra layer of insulation. This is particularly useful in colder climates where snow is prevalent.

The Role of Roofing Underlayment Manufacturers

Roofing underlayment manufacturers are responsible for creating these high-performance products that are designed to meet the specific needs of homeowners and construction professionals. They invest in the development of materials that can withstand the pressures of heavy rain and snow loads. The manufacturing process includes the use of advanced technologies and materials that offer superior strength, water resistance, and durability.

Leading roofing underlayment manufacturers use materials such as synthetic polymers, rubberized asphalt, and fiberglass to create products that are not only more durable but also lighter and easier to handle during installation. As demand for high-performance roofing underlayment grows, manufacturers are continually innovating to provide solutions that meet the needs of both residential and commercial roofing projects.

For example, a roofing underlayment manufacturer in India may focus on developing products that can withstand the country's varied climates, from monsoon rains in the coastal regions to snow-heavy conditions in the northern states. By creating materials suited to these conditions, manufacturers ensure that the underlayment performs optimally, no matter the weather.

Choosing the Right Roof Underlayment in India

When selecting roof underlayment in India, it's important to consider the specific regional climate and the kind of protection needed. In states with heavy monsoonal rains or in areas that experience snowfall, high-performance roofing underlayment is essential. The material chosen should be capable of resisting water infiltration and preventing moisture-related damage.

India’s diverse climate makes it crucial for roofing professionals to choose the right type of underlayment. While coastal areas may require underlayment that can withstand prolonged exposure to moisture, regions with cold winters may need materials that can handle ice dams and snow accumulation. In such regions, a robust roofing underlayment designed for both heavy rain and snow loads would be ideal. Roof underlayment in India can vary greatly depending on the materials used, the thickness, and the quality of waterproofing. Synthetic underlayments and rubberized asphalt are popular choices for homeowners and builders looking for long-lasting, reliable protection. Roofing professionals should work closely with suppliers to ensure that the chosen underlayment meets the specific requirements for heavy rain and snow scenarios.

The Role of Roofing Underlayment Suppliers

Roofing underlayment suppliers are the vital link between manufacturers and consumers. They provide the distribution channels for high-performance roofing materials, ensuring that contractors, builders, and homeowners have access to the products they need. Roofing underlayment suppliers not only supply the products but also offer valuable advice on installation and maintenance.

In regions with heavy snow and rain, roofing underlayment suppliers play an important role in educating their customers about the best practices for installation. A roofing underlayment supplier may offer installation guides, maintenance tips, and product recommendations to ensure that underlayment performs optimally in challenging weather conditions.

Additionally, suppliers may help with selecting the right product based on the client’s specific needs. For example, they can recommend certain underlayment types based on the local climate or advise on the most suitable material based on snow load capacity. The supplier's role is vital in ensuring that homeowners and builders select the best roofing underlayment for long-term performance.

Roofing Underlayment Installation Tips for Heavy Rain and Snow Loads

Installing high-performance roofing underlayment requires careful attention to detail, especially in regions that experience heavy rain and snow loads. Below are some tips for ensuring a successful installation:

Proper Overlap: Ensure that the underlayment is installed with proper overlap to prevent water from seeping through seams. The overlap should be at least 4-6 inches to ensure that the water flows off the roof without finding any gaps.

Installation of Ice and Water Shields: In areas prone to ice dams, it's important to install ice and water shields along the eaves of the roof. These shields provide additional protection against water infiltration during thawing periods.

Smooth Application: Ensure that the roofing underlayment is applied smoothly with no wrinkles or bubbles. Any imperfection in the underlayment can result in water penetration over time.

Seal the Edges: Properly seal the edges of the underlayment to prevent water from getting under the material. This is especially important in areas with high wind or heavy rainfall.

Layering for Added Protection: In regions that receive heavy snow loads, it may be beneficial to install multiple layers of roofing underlayment for additional protection against water seepage.

Conclusion

High-performance roofing underlayment is an essential component of any roofing system, especially in areas that experience heavy rain and snow loads. Its ability to provide protection against water infiltration, prevent ice dams, and enhance the overall durability of the roof makes it a vital part of any construction or renovation project. Roofing underlayment manufacturer are continually innovating to produce materials that can withstand extreme weather conditions, while roofing underlayment suppliers ensure that these products reach homeowners and contractors across various regions, including India. By choosing the right roofing underlayment and following proper installation guidelines, homeowners can ensure their roofs remain protected and functional, even in the harshest weather conditions.

Frequently Asked Questions (FAQs)

1. How much roofing underlayment do I need for my roof?

The amount of roofing underlayment needed depends on the size and slope of the roof. Typically, a roofing contractor will calculate the total square footage of the roof and provide an estimate of the amount of underlayment required. Most underlayment is sold by the roll, and coverage is indicated on the packaging.

2. Can I install roofing underlayment myself?

While some experienced DIYers may be able to install roofing underlayment, it is generally recommended to hire a professional roofing contractor. Proper installation is crucial for ensuring that the underlayment functions effectively, and professionals have the expertise to handle complex roofing systems.

3. What is the cost of roofing underlayment?

The cost of roofing underlayment varies depending on the type of material chosen and the size of the roof. Synthetic underlayment tends to be more expensive than asphalt felt but offers greater durability and performance. The cost can range from $0.20 to $1.00 per square foot, excluding labor.