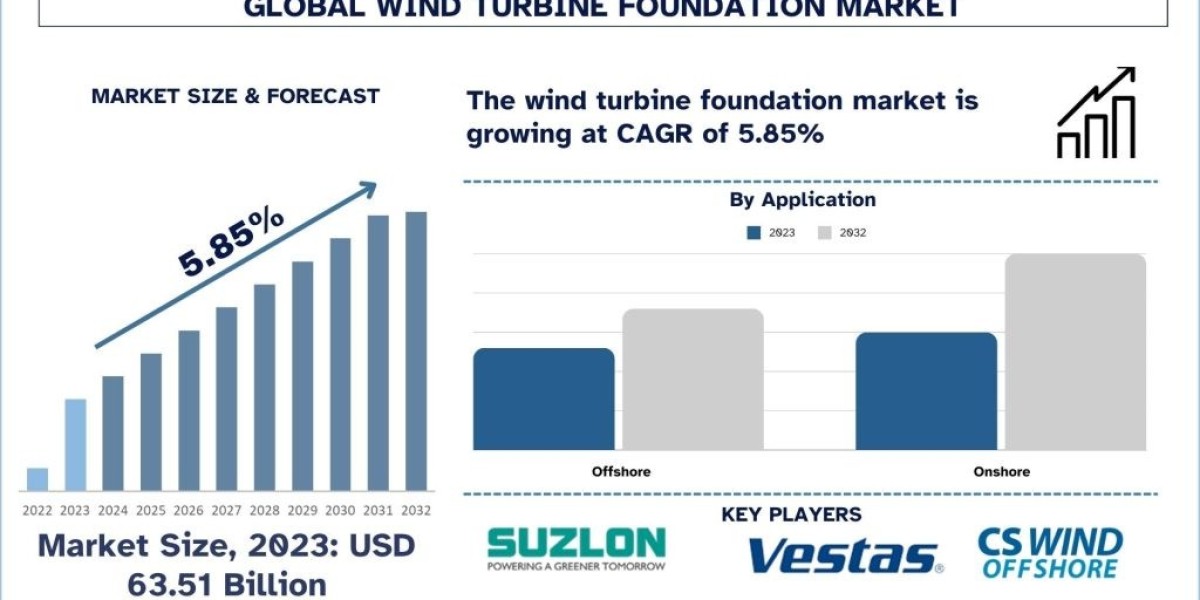

According to a new report by UnivDatos Market Insights, the Wind Turbine Foundation Market is expected to reach USD ~XX billion by 2032 by growing at a CAGR of ~5.85%. There has been a significant push worldwide to move away from traditional energy sources towards renewable energy, and wind plays a huge role in this transition. This transition significantly affects the efficiency and stability of wind turbines, which are integral to extracting energy from passing winds. The expansion of the global wind tower pipeline market would be due to the rising demand for renewable energy, the growing installation of offshore capacity, and the government support required. From the demand perspective, this article captures the overall wind turbine foundation market, emerging applications, and how it is priced into the cost.

Request To Download Sample of This Strategic Report - https://univdatos.com/get-a-free-sample-form-php/?product_id=63862

Demand:

The demand for wind turbine foundations is directly related to the expansion of the overall wind energy industry. Due to worldwide endeavors of countries to develop clean energy and cut carbon emissions, the installation of wind turbines has soared. According to the Global Wind Energy Council (GWEC), global wind power capacity had risen to 743 GW by the end of 2020, doubling it before an anticipated double in their number for the next decade. This rapid expansion of the installed capacity for wind turbines directly impacts the demand for foundations to support these installations. The demand is driven by the growing need for cleaner energy solutions, heightened concerns about secure and sustainable power sources, and falling costs in wind supply chains. In addition to further advancements in turbine technology making more extensive and efficient units, increasing requirements of a stable foundation are some factors driving tower base spec sheets. This has driven a significant increase in the need for special foundations that can endure harsh marine environments, with the offshore wind sector notably experiencing swift expansion.

Applications

Wind turbine foundations play a crucial role in ensuring the stability and performance of wind turbines. They are designed to support the entire structure, including the tower, nacelle, and rotor blades, and to transfer loads to the ground or seabed. The primary applications of wind turbine foundations can be categorized into onshore and offshore segments.

Onshore wind farms are the most common application of wind turbine foundations. These foundations are typically constructed using reinforced concrete, steel, or hybrid materials. The most prevalent types of onshore foundations include:

1. Gravity-based Foundations: These are large concrete structures that rely on their weight to provide stability. They are ideal for areas with stable ground conditions.

2. Pile Foundations: Ideal for softer soil areas; this foundation type consists of steel or concrete piles driven deep into the earth to provide support.

3. Hybrid Foundations: They combine gravity-based and pile-supported structures, providing versatility to match various soil conditions.

Offshore Foundations

Due to challenging marine conditions, offshore wind farms require more complex and specialized foundation solutions. The primary types of offshore foundations include:

1. Monopile Foundations: Single, large-diameter steel piles driven into the seabed. Monopiles are suitable for shallow to moderate water depths.

2. Jacket Foundations: Consisting of a lattice framework of steel beams, jacket foundations are used in deeper waters. They offer excellent stability and load distribution.

3. Gravity-based Structures (GBS): Similar to onshore gravity-based foundations, GBS are massive concrete structures placed on the seabed. They are suitable for shallow waters and require extensive seabed preparation.

4. Floating Foundations: For deep-water applications, floating foundations anchored to the seabed with mooring lines provide a viable solution. These are still in the early stages of commercialization but show significant potential.

Cost:

The cost of onshore foundations is relatively less expensive than that of offshore foundation installations, but it comes with marine complexities and challenges. Onshore foundation costs are typically between $100,000 and $300,000 per turbine, depending on the type of foundation. Gravity foundations cost less but use a lot of material and labor. Under these circumstances, pile foundations will become technically justified, albeit more costly, but they guarantee satisfactory performance in soft soil conditions.

Offshore foundation costs are considerably higher, ranging from $1 million to $5 million per turbine. Though relatively cost-effective for shallow waters, monopile foundations become expensive in deeper waters due to the need for longer piles and specialized installation vessels. Jacket foundations and gravity-based structures incur higher costs due to their complex designs and installation processes. Still, in the nascent stage, floating foundations present a higher upfront cost but offer potential long-term cost savings as technology advances.

Manufacturing

Manufacturing wind turbine foundations involves a combination of civil engineering, structural design, and material science. Critical steps in the manufacturing process include design, material procurement, fabrication, and installation.

1. Design: Foundation design is critical considering site-specific conditions, turbine specifications, and load requirements. Advanced software and modeling techniques optimize designs for stability and cost efficiency.

2. Material Procurement: High-quality materials such as steel, concrete, and composite materials are sourced to ensure the durability and performance of the foundations. Sustainability considerations are increasingly influencing material choices.

3. Fabrication: The fabrication process involves the construction of foundation components in controlled environments. This often occurs in specialized shipyards or fabrication yards for offshore foundations.

4. Installation: Installing wind turbine foundations is complex and resource-intensive. Onshore foundations are typically cast in situ, while offshore foundations require specialized vessels and equipment for transportation and installation.

Ask for Report Customization - https://univdatos.com/get-a-free-sample-form-php/?product_id=63862

Conclusion

The global wind turbine foundation market is poised for continued growth, driven by the increasing adoption of wind energy as a sustainable power source. The demand for robust and reliable foundations is set to rise with the expansion of both onshore and offshore wind farms. Technological advancements, cost optimization, and the development of innovative foundation solutions will play pivotal roles in shaping the future of this market.

As the world moves towards a greener and more sustainable energy future, the wind turbine foundation market will remain a cornerstone of the wind energy industry. With ongoing research, investment, and collaboration among industry stakeholders, the challenges associated with foundation design, manufacturing, and installation will be addressed, ensuring the efficient and reliable harnessing of wind energy for future generations.