As a writer, I am excited to delve into the fascinating world of lsr silicone molding. This innovative technology has revolutionized the manufacturing industry by offering numerous advantages in terms of customization and efficiency.

The Advantages of LSR Silicone Molding

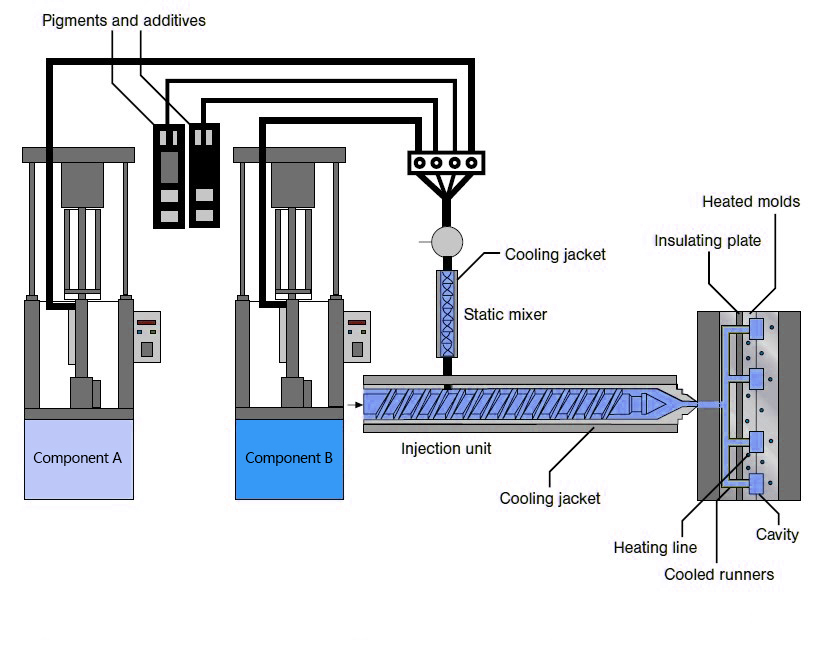

LSR silicone molding is a highly versatile process that allows for precise and intricate designs. It offers exceptional flexibility, durability, and resistance to extreme temperatures, making it ideal for various applications such as medical devices, automotive parts, and consumer products.

This advanced molding technique enables manufacturers to create complex shapes with high precision while maintaining consistent quality throughout production. The liquid nature of silicone ensures that even the most intricate details are accurately replicated in every mold.

In addition to its excellent physical properties, LSR silicone molding also provides cost-effective solutions. Its efficient production process reduces waste materials and minimizes labor costs compared to traditional manufacturing methods.

JVTECH: A Leader in LSR Silicone Molding

When it comes to expertise in LSR silicone molding, JVTECH stands out as a leading company in this field. With years of experience and cutting-edge technology, they have successfully delivered customized solutions for various industries worldwide.

JVTECH's team of skilled engineers works closely with clients from concept development to final production stages. They offer comprehensive services including design optimization, prototyping, tooling fabrication, and mass production – ensuring seamless integration into their customers' supply chains.

By leveraging their extensive knowledge and state-of-the-art facilities equipped with advanced machinery specifically designed for LSR silicone molding processes, JVTECH consistently delivers superior quality products within tight deadlines.

Click what is 2k injection molding.

What is 2K Injection Molding?

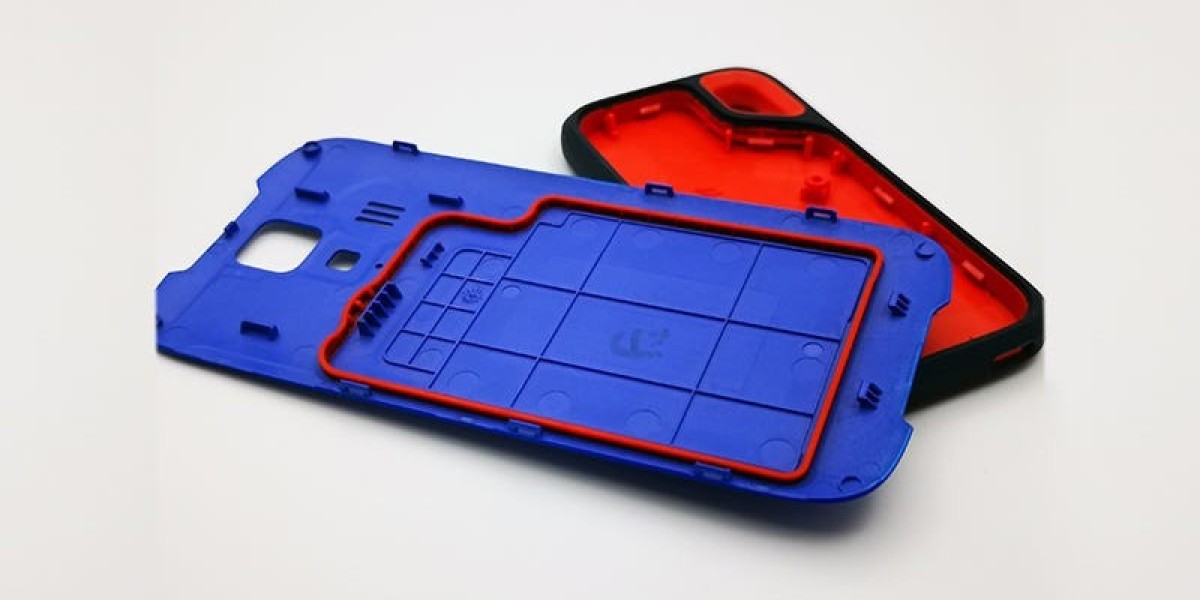

2K injection molding is another innovative technique that complements LSR silicone molding. It involves the use of two different materials or colors in a single mold, resulting in enhanced functionality and aesthetics.

This process allows for the combination of rigid and flexible components, creating products with varying hardness levels within a single part. 2K injection molding offers increased design possibilities while reducing assembly time and costs.

By incorporating both LSR silicone molding and 2K injection molding technologies, manufacturers can achieve even greater customization options, enabling them to meet specific requirements and deliver unique solutions to their customers.

In Conclusion

LSR silicone molding has revolutionized the manufacturing industry by offering exceptional flexibility, durability, precision, and cost-effectiveness. Companies like JVTECH have played a crucial role in advancing this technology through their expertise and state-of-the-art facilities. When combined with techniques such as 2K injection molding, manufacturers can unlock endless possibilities for customization. As we continue to explore new frontiers in manufacturing processes, LSR silicone molding remains at the forefront of innovation.