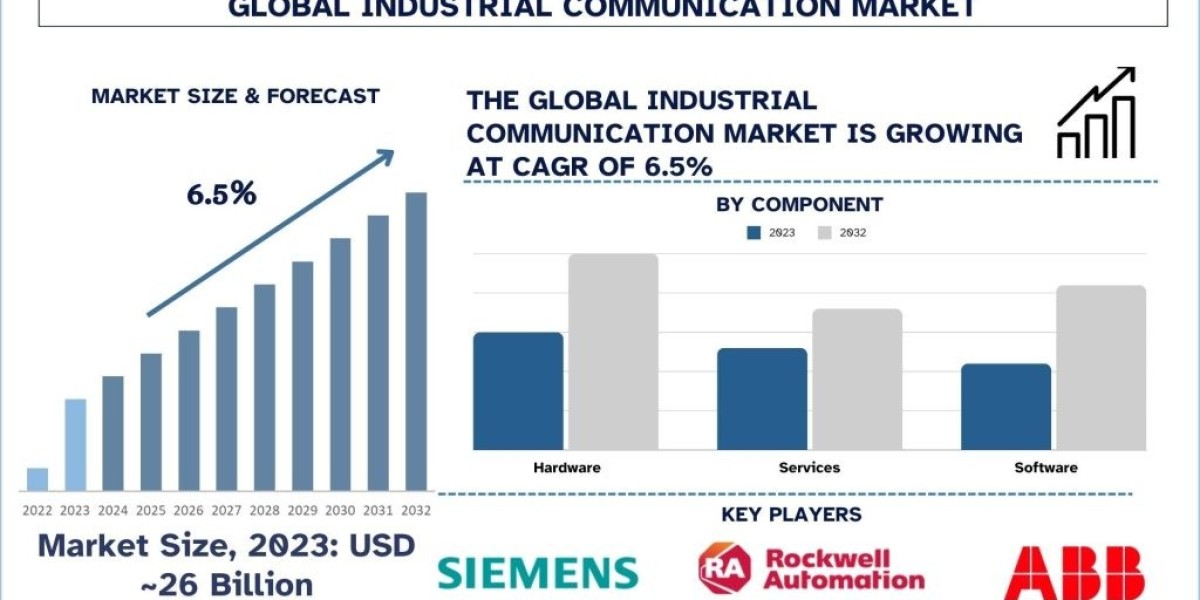

According to the UnivDatos Market Insights analysis, the rise of IIoT (Industrial Internet of Things), increasing adoption of wireless communication, expansion of industrial automation in emerging markets, and increasing focus towards Industry 4.0 and smart manufacturing drive the Industrial Communication market. As per their “Industrial Communication Market” report, the global market was valued at USD 26 Billion in 2023, growing at a CAGR of about 6.5% during the forecast period from 2024 - 2032 to reach USD billion by 2032. Industrial communication is a concept that is fundamental to modern manufacturing and automation that enables smart factories and connected industries. With the evolution in the industrial setting and the increase in the demand for competence, accuracy, efficiency, and security in communications, there is a need to establish more efficient communication networks in the industrial setting. The industrial communication market is advancing at a great fast pace due to market drivers such as Industrial Ethernet, IIoT, and the upcoming 5G. In this article, the reader is introduced to various contemporary trends that have emerged in the setting of industrial communication and the role these trends play in shifting industries across the globe.

Access sample report (including graphs, charts, and figures): https://univdatos.com/get-a-free-sample-form-php/?product_id=65422

1. The Rise of Industrial Ethernet

It can be identified that Industrial Ethernet is one of the strongest trends associated with industrial communication. The currently dominant type of Fieldbus, the legacy Traditional Fieldbus systems, are slowly fading into eclipse in favor of Ethernet-based solutions. The Industrial Ethernet has the following features compared to its predecessors: higher bandwidth, greater scalability, and higher reliability. These features are very important in today’s manufacturing processes where there is a need to interconnect several devices for real-time data sharing and integration.

For instance, on July 1, 2024, Moxa launched its high-bandwidth Ethernet switch portfolio, new MRX Series Layer 3 rackmount Ethernet switches that support 64 ports with up to 16 ports of 10GbE speed to accelerate data aggregation for industrial applications, and help users build high-bandwidth network infrastructure to realize IT/OT convergence with the EDS-4000/G4000 Series Layer 2 DIN-rail Ethernet switches supporting 2.5GbE uplink options.

Ethernet-based protocols like PROFINET, EtherNet/IP, and Modbus TCP are finding more acceptance due to their capability to handle industrial applications. These protocols enable coexistence with other devices and systems and, thereby, avoid hitch-free times and enhance general performance. Resultingly, the global adoption of Industrial Ethernet is most evidently noted in industries like Automotive, Foods and Beverages, and Pharmaceuticals industries, among others, where precision and reliability are highly sensitive.

2. Adoption of IIoT and Smart Manufacturing

The technology referred to as the Industrial Internet of Things or IIoT is revolutionizing industries to the level in which connected machines, sensors, and devices can connect to the Internet. This integration enables monitoring, data processing and even predicting faults in a system hence increasing efficiency and reducing costs of operations. Another area in which IIoT is a major factor is the industrial communication market since this is used extensively to ensure that a range of communication networks perform optimally.

Smart manufacturing which is closely related to IIoT has begun to trend in the plants and factories of different industries. It entails the integration of superior techniques including AI, machine learning as well as big data in enhancing manufacturing procedures and decision-making processes. For smart manufacturing to work, a reliable and high rate of data communication is required and this can only be provided by communication networks. This has therefore resulted in high demands for industrial communication interfaces that can be able to support the high traffic that is encompassed by smart devices.

An example of How IIoT has been put to work is through the use of digital twins in the production process. A digital twin is a digitized model of an object that can mimic its operations like a machine or formation line and be used in a predictive manner for better understanding. Digital twins’ implementation depends on the quality and timeliness of information that can only be provided by strong industrial communication networks.

3. The Role of 5G on Industrial Communication

Industrial communication is waiting for the arrival of 5G networks as it is going to transform the way it is connected through enhanced ultra-fast connection with a low latency period. 5G can provide access rates up to 100 times faster than 4G; the latency which limits the time it takes for data to travel is as low as one millisecond. The above capabilities are however useful for industries that need control and automation in real time like manufacturing, logistics, and energy.

Another major benefit that was showcased in the context of the 5G networks is the possibility to connect and activate a large number of devices at the same time. This makes it suitable for IIoT use because one can reach thousands of sensors and other machines that may be required for real-time communication. Also, low latency is necessary for applications where any minor time is a crucial factor, for instance, robots, drones, and other controlled equipment.

On 28 September 2023, Siemens launched a private infrastructure developed in-house for the 5G mobile communications standard. The solution enables industrial companies to build their own local 5G networks that will provide optimal support for automation applications.

Companies are already looking into applying 5G in industrial communication although it isn’t very widespread as of now. For example, through the implementation of 5G technology automotive manufacturers launched the so-called vehicle-to-everything (V2X), which provides the ability for cars to communicate with each other and even with signals such as traffic signals and road signs. This not only makes the road safer to use but also allows efficient flow of traffic on the roads.

4. Effective measures for improving cybersecurity in Industrial Communication

In recent decades, with the development of industrial communication networks more and more complicated, cybersecurity is one of the main issues. There are new threats that appear as a result of enhanced connectivity through IIoT and with the help of 5G technology. An industrial communication network may be severely damaged in the event of a successful cyberattack, which results in production loss, unauthorized access to information, and destruction of important structures.

To this end, there is a heightened focus on implementing sophisticated cybersecurity measures to secure industrial communication networks that firms use. This includes encryption measures that are used to ensure the safety of data that is being transferred through a network as well as firewalls that are meant to prevent unauthorized individuals from accessing the firm’s network or system. Also, there is increased concern with the protection of the supply chain which has made it difficult to introduce compromised components in the industrial networks.

In addition, governments and other regulatory authorities are also coming forward to improve the rate of cybersecurity in industrial communications. For instance, the European General Data Protection Regulation and the U. S Cybersecurity Act enacted in 2015 imposes certain stringent conditions as regards the protection of data and sharing of information respectively. Failure to meet these regulations is perhaps one of the reasons that have seen many industrial communication market firms struggle to stay afloat.

5. The Increasing Relevance of Edge Computing

Another trend that characterizes industrial communication is edge computing. It means data processing is performed at the edge of the network which is closer to the source of data generation other than going to central cloud servers. This approach minimizes latency, bandwidth consumption, and possibilities of data leakage making it ideal especially for real-time use in industries.

For instance, on January 29, 2024, Moxa Inc., a leader in industrial communications and networking, officially announced the launch of a new family of x86 industrial computers (IPCs) with exceptional reliability, adaptability, and longevity to address the increasing demands of data connectivity and real-time processing of large volumes of sensor and device data at the industrial edge.

Click here to view the Report Description & TOC https://univdatos.com/report/industrial-communication-market/

Conclusion

The market for industrial communication is set to grow because of the ongoing trend situation like Industrial Ethernet, IIoT Integration, 5G Deployments, Cybersecurity, and Edge Computing. All these trends are not only changing Industries but also calling for innovations in automation, control, and smart manufacturing. With many corporations devoting funds to modern communications technologies, the industrial communication market remains poised to dominate the future of linked industries.

Related Report

Cyber Insurance Market: Current Analysis and Forecast (2024-2032)

Digital Human Avatar Market: Current Analysis and Forecast (2024-2032)

Virtual Influencers Market: Current Analysis and Forecast (2024-2032)

Diversity and Inclusion (D&I) Market: Current Analysis and Forecast (2024-2032)

Container Orchestration Market: Current Analysis and Forecast (2024-2032)

Contact Us:

UnivDatos Market Insights

Email - contact@univdatos.com

Contact Number - +1 9782263411

Website - https://univdatos.com/