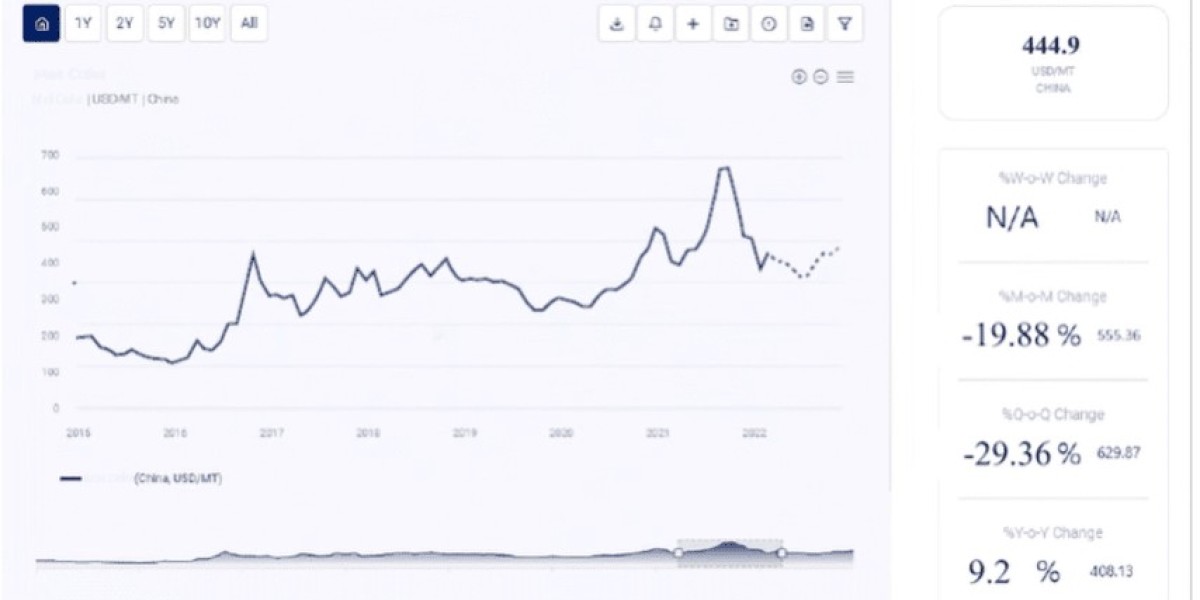

Production operators are essential to manufacturing, responsible for setting up, operating, and maintaining machinery that produces goods across various industries, such as automotive, electronics, pharmaceuticals, and food processing. The Production Operator Wages chart are influenced by factors like demand for skilled labor, economic conditions, industry growth, and geographic location. This article explores historical trends in production operator wages, the factors driving these trends, and the future outlook for wages in this field.

1. Overview of Production Operator Roles and Responsibilities

1.1 What is a Production Operator?

A production operator is responsible for running and maintaining equipment in a manufacturing setting. Their duties typically include:

- Setting Up Machines: Preparing machinery for production runs, including calibrating, programming, and performing pre-checks.

- Operating Equipment: Running machinery and monitoring output to ensure it meets quality and quantity standards.

- Quality Control: Checking products for defects, making necessary adjustments to improve quality, and ensuring adherence to production specifications.

- Maintenance and Troubleshooting: Performing basic machine maintenance, troubleshooting minor issues, and escalating larger issues to maintenance teams when needed.

- Health and Safety Compliance: Following health and safety protocols to maintain a safe working environment and minimize workplace hazards.

1.2 Key Industries for Production Operators

Production operators work in a wide range of industries, including:

- Automotive Manufacturing: Operating equipment to assemble vehicles and automotive components.

- Pharmaceuticals: Running machinery to produce and package medications and medical supplies.

- Electronics: Assembling electronic devices and components.

- Food Processing: Operating equipment for food and beverage processing and packaging.

- Chemical Processing: Handling machinery for mixing, processing, and packaging chemicals.

Enquire For Regular Prices: https://www.procurementresource.com/resource-center/melamine-resin-price-trends/pricerequest

2. Historical Production Operator Wage Trends

2.1 2000 to 2010

Between 2000 and 2010, production operator wages showed moderate growth, driven by factors such as inflation and gradual increases in demand:

- Steady Demand Growth: As the manufacturing sector expanded, demand for skilled production operators increased, leading to gradual wage growth.

- Inflation-Driven Wage Adjustments: Wages saw moderate increases to keep pace with inflation. Wage adjustments helped maintain purchasing power for production operators in line with the cost of living.

- Outsourcing and Automation: During this period, outsourcing and automation in manufacturing increased, which put downward pressure on wage growth, particularly in developed economies. However, skilled production operators remained in demand for roles requiring specialized knowledge.

2.2 2011 to 2019

From 2011 to 2019, production operator wages experienced faster growth, influenced by economic recovery, increased demand for skilled labor, and regulatory changes:

- Post-Recession Economic Growth: As economies recovered from the 2008 financial crisis, the manufacturing sector saw renewed investment, driving demand for skilled production operators and supporting wage increases.

- Skill Shortages: Increased demand for skilled labor and the need for more technically adept operators led to wage growth as employers sought to attract and retain qualified candidates.

- Higher Health and Safety Standards: Stricter health and safety regulations led to increased training requirements, driving demand for skilled workers and contributing to wage increases in roles that required specialized safety knowledge.

By the end of this period, production operator wages were generally higher, reflecting both increased demand for labor and the need for technical skills in a more automated manufacturing environment.

2.3 2020 to Present

Since 2020, production operator wages have experienced significant growth due to the COVID-19 pandemic, supply chain disruptions, and shifts in labor market dynamics:

- COVID-19 Pandemic Impact: The pandemic disrupted supply chains and increased demand for certain manufactured goods (such as medical supplies), putting pressure on employers to fill production roles. In response, wages increased to attract labor.

- Labor Shortages and Demand for Skilled Workers: Labor shortages in the manufacturing sector, driven by pandemic-related disruptions, retirements, and skill gaps, have led to higher wages as employers compete for qualified workers.

- Inflation and Cost of Living Adjustments: Rising inflation since 2021 has led employers to increase wages to maintain purchasing power for production operators, particularly in regions with high costs of living.

- Shift Toward Automation and Technical Skills: Increased investment in automation has raised demand for production operators with technical skills. Employers are offering higher wages to attract operators with the skills needed to manage and maintain automated machinery.

As of 2023, production operator wages are elevated, reflecting demand for skilled labor, labor shortages, and increased competition among employers.

3. Factors Influencing Production Operator Wages

3.1 Industry Demand

Industry-specific trends significantly impact production operator wages:

- High-Demand Sectors: Industries experiencing rapid growth, such as pharmaceuticals, electronics, and food processing, are more likely to increase wages to attract operators.

- Specialized Knowledge Requirements: Some sectors require operators to have specialized knowledge, such as food safety certifications or pharmaceutical production experience, which can lead to higher wages.

3.2 Geographic Location

Location plays a crucial role in determining production operator wages:

- Cost of Living: In regions with high living costs, such as urban areas or areas with high housing costs, wages tend to be higher to compensate for increased living expenses.

- Availability of Skilled Labor: Regions with fewer skilled workers often offer higher wages to attract and retain talent. Additionally, rural or less populated areas may offer competitive wages to attract skilled labor from urban centers.

3.3 Technological Advancements and Automation

The increasing use of automation in manufacturing impacts wages in various ways:

- Skill Requirements: With the adoption of automated machinery, production operators are often required to have more technical skills, such as the ability to troubleshoot equipment and manage computer systems. Higher skill levels generally lead to higher wages.

- Shift in Job Roles: Automation has changed the nature of production operator roles, creating demand for multi-skilled operators capable of handling both traditional tasks and automated systems, leading to wage increases for these roles.

3.4 Economic Conditions and Inflation

Broad economic trends, such as GDP growth, unemployment rates, and inflation, impact production operator wages:

- Economic Expansion and Recession Cycles: During periods of economic growth, manufacturers typically increase production, leading to higher demand for operators and wage growth. Conversely, during economic downturns, demand for production labor can decrease, potentially limiting wage growth.

- Inflation: Rising inflation, as seen in recent years, prompts employers to raise wages to maintain real income levels for production operators. In high-inflation environments, wage growth tends to accelerate to keep pace with rising living costs.

3.5 Labor Shortages and Demographic Shifts

Labor market dynamics, including skill shortages and demographic changes, influence production operator wages:

- Aging Workforce: As the manufacturing workforce ages, retirements create skill shortages, leading to wage increases as employers compete for younger, skilled workers to fill vacant positions.

- Skill Gaps: Many industries report skill gaps in technical areas. Employers are increasingly offering higher wages to attract and retain operators with specialized skills needed for modern manufacturing environments.

4. Future Outlook for Production Operator Wages

Several factors are expected to shape the future of production operator wages:

4.1 Ongoing Demand for Skilled Labor

As manufacturing continues to advance, demand for skilled production operators will likely remain strong. Growth in industries such as electronics, automotive, and pharmaceuticals will support sustained demand for skilled operators, leading to continued wage growth in these sectors.

4.2 Impact of Automation and Upskilling

With continued investment in automation, the role of production operators will evolve, requiring higher levels of technical skills. Upskilling initiatives and training programs will help workers adapt to these changes. Wages for operators with technical skills and experience in automated systems are expected to grow faster than those for operators in more traditional roles.

4.3 Influence of Inflation and Cost of Living

Rising inflation and cost of living concerns will likely prompt further wage increases to maintain purchasing power for production operators. Companies may continue to adjust wages in response to inflationary pressures, especially in high-cost areas.

4.4 Demographic Shifts and Labor Market Dynamics

As experienced operators retire, labor shortages may increase, particularly in regions with limited access to skilled labor. Employers may respond by offering competitive wages and benefits to attract new talent. Additionally, manufacturers may invest more in training and development to bridge the skill gap.

4.5 Shift Toward Sustainable Manufacturing Practices

As sustainability becomes a greater focus in manufacturing, demand for operators with knowledge of sustainable practices may grow. Operators in industries moving toward eco-friendly practices may see wage increases as companies invest in skilled workers capable of meeting these goals.

Contact Us:

Company Name:Procurement Resource

Contact Person: Leo Frank

Email: sales@procurementresource.com

Toll-Free Number: USA Canada — Phone no: +1 307 363 1045 | UK — Phone no: +44 7537 132103 | Asia-Pacific (APAC) — Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA